Business solutions

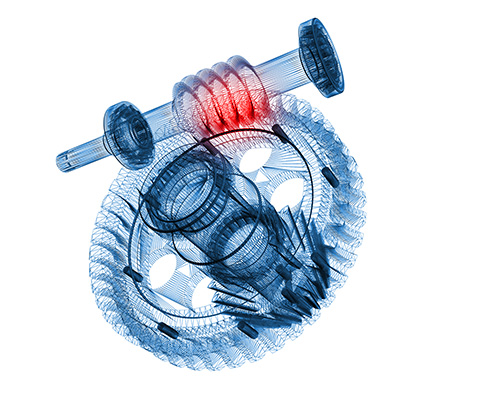

Machinery diagnostics

When operating rotating machinery, the vibroacoustic diagnostics is a perfect tool to assess the technical condition and identify sources of dynamic forces.

Alignment of machine shafts

Precise laser alignment of machine shafts ensures much longer life of bearings, seals and other operating parts.

Thermal imaging

With a thermal imaging camera, it is possible to detect the areas in machines and equipment with improper temperature.

Geometry checks

Measurements of straightness and flatness with laser are considered to be the most accurate methods. Since the laser beam does not deflect, the measurements are reliable and repeatable.

Dignostic monitoring

Systematic monitoring of a large number of machines with statistical methods of condition assessment enables considerable reduction of the cost of diagnostics.

Balancing machinery rotors

Balancing machinery rotors in their bearings is the best method to eliminate dynamic imbalance and related vibrations.